+8615061447755

The main content of daily maintenance of pile drivers is to apply lubricating oil and butter, mainly for the parts with greater friction during work, to ensure the lubrication effect, to ensure the efficiency, stability, safety and durability of pile drivers in daily operations. Let me introduce to you how to simply maintain pile drivers every day. Note: Every day!

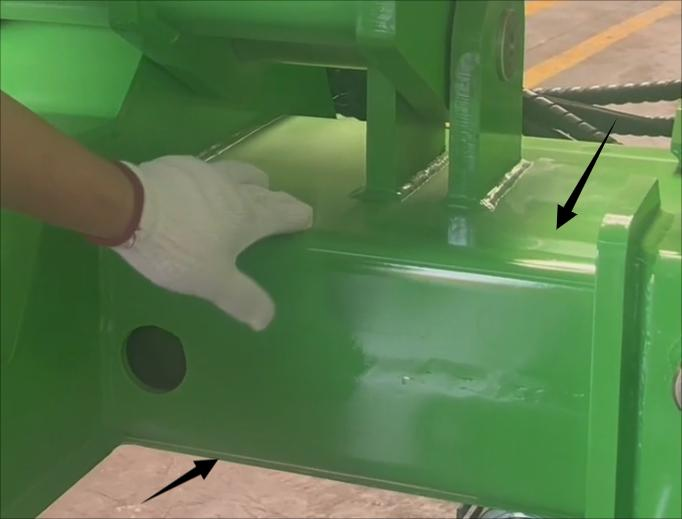

1.The sides and front of the horizontal telescopic guide rail should be lubricated once a day to ensure smooth working surface, and observe whether there are debris, stones, and iron filings sucked in.

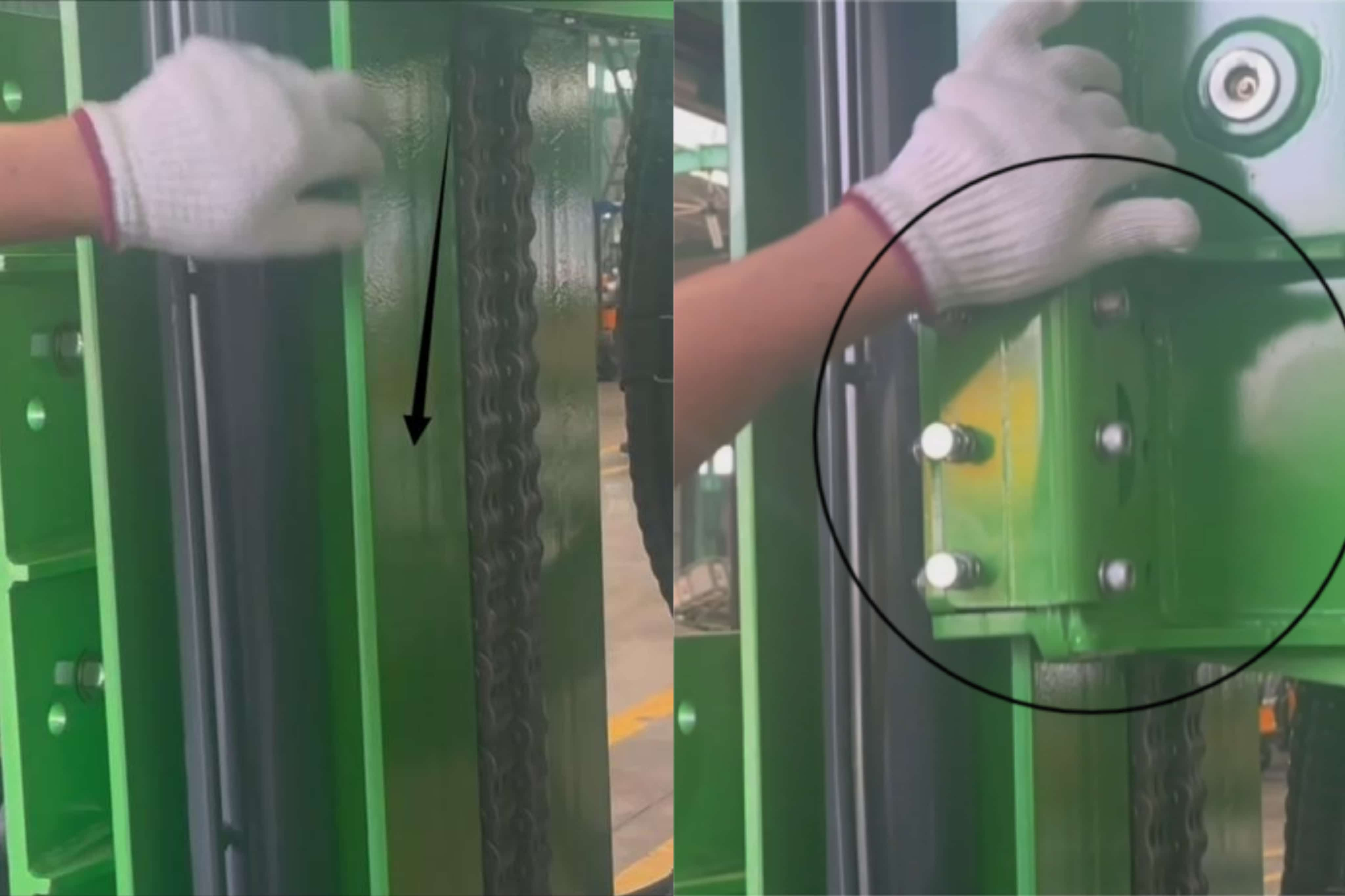

2. The working surface of the vertical guide rail and the interface with the wear-resistant block need to be lubricated once a day.

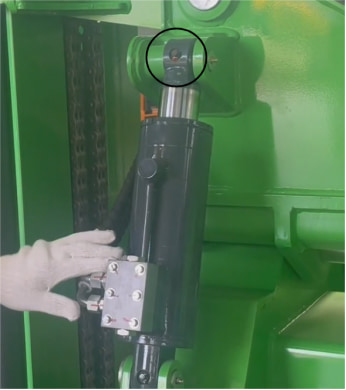

3. Each pile driver has multiple oil cylinders, and each oil cylinder has a grease nipple at the hinge point of the pin hole at the top, which needs to be injected with grease once a day.

4.The pin ends at the working position are all embedded with grease nipples, which need to be injected with grease once a day.

5. The working chain of the vertical guide rail (if the guide rail has a chain) needs to be lubricated with engine oil before work, and the debris, stones and iron filings attached to the chain should be cleaned up in time after work.

6. Check if any screws are loose. If so, tighten them immediately.

7.Check the connection surfaces of hydraulic components and all pipe joints of oil circuits for leaks.

8.Check the hydraulic oil level to ensure that the oil level is within the normal range.

In summary, all parts with more friction should be lubricated, and all grease fittings of oil cylinders and pins should be filled with grease. If there is a chain, you need to apply engine oil. Note that these are daily maintenance tasks that need to be done every day!

Here I would like to give a suggestion to the contractors of photovoltaic projects and road guardrail construction projects: solar pile drivers and highway guardrail pile drivers, which have a relatively harsh working environment, must pay attention to daily maintenance. Three points of use and seven points of maintenance, or it can be understood as the 2-8 principle, using less than 20% of the time every day to maintain the machine can bring 70% more work efficiency. Daily routine maintenance can greatly reduce the probability of machine failure, thereby greatly improving economic benefits. I hope everyone can pay more attention to the daily maintenance of the machine!

Our hours

Whether it is a holiday or a festival, we will have someone to receive you 24 hours a day and respond to you in the shortest time.

Hi! Click one of our members below to chat on